Now if you want to practice your driving skills, I have set up a simple scenario which is downloadable at the download section at SimTogether. Once you entered the download section search and find: "Departure - Time to pop off".

This scenario is available soon after publication of this Blog. In this scenario you will start at Hagen Freight Yard and you will haul a standard tfreight train towards Hohentlimburg siding. This run takes about 16 minutes and when you practice your driving skills please refer to this blog in order to drive the engine properly. You need only the Ruhr-Sieg line in order to run this scenario. Furthermore this option: A better update of the sounds of the engine. The improved sounds of the Br52 can be found here. If you do not wish to update it will not affect the scenario. So don't worry.

When you have test your brakes according to my last blog you are now ready to hook on your train and get prepared for the real job. When anything look okay to you, you now get prepared to roll and hook on your train from the starting location. Most of the times you are at the depot near the station where you need to pick up your train to start your shift.

Now check out the boiler pressure and open up the blower by pressing [ N ] until the blower is fully opened.

Open up the dampers by pressing [ M ] this provides oxygen from underneath the the fire into the fire mass through the fire grate.

This will increase the boiler pressure.

- Now set the reverser in the proper direction and lock at about 30% cut-off.

- Open the steam driven air pump.

- Release the train brake and independent brake and open up the regulator by hammering the latch/regulator away from you with your left arm [ A ]. Release the hand brake by pressing [ / ] if not set.

- The engine should start rolling right now.

- Adjust the steam flow by regulating the regulator pressing [ A ] or [ D ] depending the speed and boiler pressure.

As you have reached 25 km/h (15 Mph) shot of the regulator, but not completely. Keep the regulator a fraction open so steam will still flow through the cylinder blocks but will not use the steam power. Let the engine roll towards the right train and check out your boiler pressure and water gauge.

- Once reaching your train shut of the regulator on approaching your train.

- Watch the pressure gauge regularly in order to prevent a pressure drop.

- Open the cylinder cocks. [ C ]

-

Be sure the water is at least 2/3 of a glass

You can check this out at the water glass. 1/3 should be empty. - Adjust the independent brake to slow down at about 2 km/h.

- Shut off or adjust the regulator in order to keep rolling with very low speed.

- Adjust the brakes so you are rolling out against your train.

-

Be sure your coupling speed is about 0,5 km/h other wise stop before your train and then move up slowly

keeping the reverser cut-off at 30% and adjusting the regulator until you slowly pick up some speed. - Roll out against your train and bump softly the buffers of the wagon rack.

- Now set the independent brake or hand brake.

- Now when you have stopped at your rack of wagons "jump out" of your engine [ 8 ] and navigate to the back of your tender/engine and hook on your train hovering over the coupler until the mouse changes into a coupler symbol and right-click on the coupler.

The coupling action will now execute and now you need to get back to the footplate [ 1 ].

- Get on the footplate and apply the train brake and watch the needle of the train brake gauge descent untill 4,7 bar is reached.

- Release the train brake and watch the needle increase towards 5,5 bar.

- Set the reverser at 70% Cut-Off.

- Once the 5,5 bar is reached set the train brake lever in the middle position.

Now when you have test your brakes you are now ready to hook on your train and get prepared for the real job. When anything look okay to you, you now get prepared to roll and hook on your train from the starting location. Most of the times you are at the depot near the station where you need to pick up your train to start your shift.

- Look out the window and if there is no one at the platform close to the train you now pop off to your destination.

- Open te regulator by hammering the regulator manually until you start to roll.

- When rolling for about 25 meter close the cylinder cocks [ C ].

- Set the reverser back to about 60% and adjust the regulator.

- As you now pick up speed set the reverser further back to about 50% cut off.

- Now watch the boiler pressure.

Once you have almost reached the speed limit make sure you find your balance by adjusting regulator, reverser, speed and boiler pressure. This is one of the most harshest moments because you need to find the right balance so you don't loose speed, neither boiler pressure.

- Now adjust the reverser and regulator so the boiler pressure is increasing but do not loose any speed.

- Make sure the blower is still on [ N ] ( to reduce the blower; press [ Shift ] - [ N ] to adjust )

- Open the fire door [ F ]

- Start shoveling [ R ] and shovel coal on the fire grate.

-

Shovel about 6-10 scopes of coal on the fire grate.

The fire mass must increase in the fire chaimber. - To stop shoveling, press [ Shift ] - [ R ]

- Do not shovel more than 10 scopes of coal in one time.

- Close the fire door [ Shift ] - [ F ].

- Check the boiler pressure.

Now when you have done this you are almost ready with the first sequence, but now you need to inject water into the boiler.

The engine normally has two injectors or one injector and one feeder pump. MOst German engines has a steam driven feeder oump and a automated semi-self-working injector.

Smaller engines often has a simple injector. Your engine Br 52 has 2 simple injectors. and to operate these injectors will go in a strict sequence. Both injectors works the same way.

An injector contains two funnels in a tube pointed to each other. An other funnel is also included and pointed in the same direction and is placed just behind an other funnel. This funnel provides steam to the water.

Once steam is blown into the water at high speed the steam will expand in the water due to the temperature difference. This reaction gives the water the pressure its pressure and due to that pressure the water will get injected into the boiler passing some safety valves and the water level in the boiler will increase.

BE AWARE: HOT water is NOT working so when the water is hot the injection principe will not work or will cease injecting.

The greater the difference in temperature the more force the injector will obtain.

When the steam force is too much water will overflow and leak out of the drain tube which is fitted at the injector.

In this case you need to adjust the water and steam flow in orde to get the injector back to work.

At the Br 52 this is not simulated. An engine that simulates the proper working of the injector is for example the:

Just Trains Advanced engines like the British Standard classes.

Now you are driving.

It is now important to maintain speed and shovel or inject water during driving.

Every 2-3 minutes you shovel and every 2-3 minutes you inject water.

DO NOT shovel and inject simultaniously!!! The possibility of a blow back of fire is at hand.

Be sure the coal level at the fire grate should be at least 75% and the water level should be at least 70% not exceeding 85%.

The Br 52 will run the best maintaining these values. Normally you shovel about 1000 kg at 50 km and will use approximately 1000 liter of water at normal speed. On shunting purposes you even use twice as much water in a half hour.

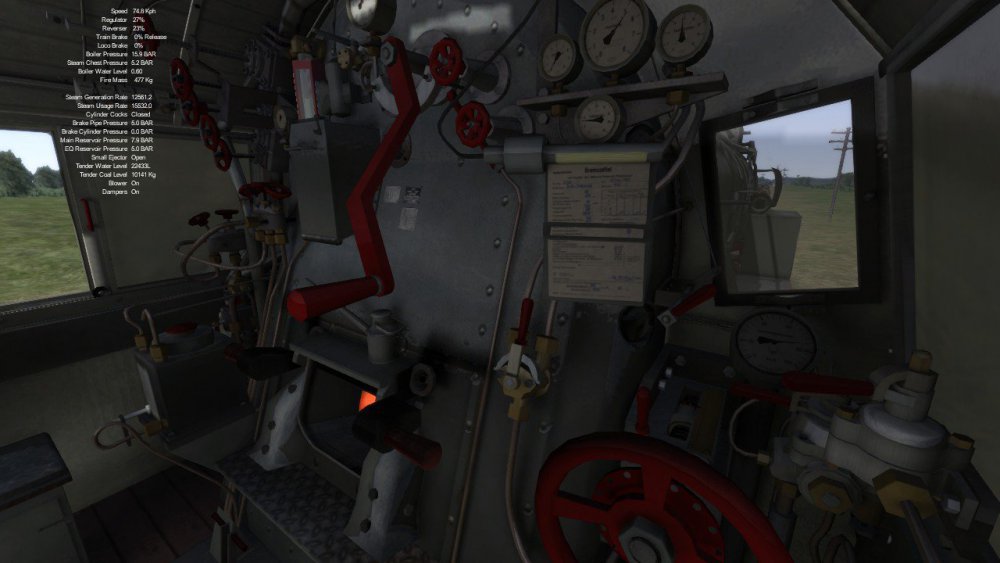

You can read the engine values by pressing [ F5 ] two times. White text will appear in the upper left corner with all necessary information. Once you get the hang of driving you do not need added information like [ F5 ].

Now the situation is this when you have followed al these instructions: You did not need the HUD !!!!!!

This way of driving is as realistic as possible.